SEALS Automatic Screw Feeder, CM-30, could keep the low noise and less scratch of screw surface in material hopper due to its up-and-down pushing board design. With Fiber Optic control, it also reduce noisy and saving power while it is full in chute. By the air blow feeding system, you can get the next screw within 0.5 second in jaw before you move to the next fasten position. No need to pick screw, no need to put screw into drive bit and prevent rust due to hand sweating.

Meanwhile, the telescope type screwdriver set deliver the downward force into the sleeve of screw. It is quite essential for self tapping screw and wood screw.

For automation integration, the screw feeder can be control to air blowing one screw by giving a dry contact. And, the screwdriver also can be installed into a cylinder for fastening stroke action in fully automation assembly line.

Features

1. Remarkable Operation Efficiency Improvement

Just like an ordinary screwdriver, the automatic screw is operated with only one hand, and achieves an operating speed of 20-30 screws per minute. It saves you the effort of picking up, moving and positioning the screws.

2. Easy-to-use Compact Construction

By adopting the highly reliable Blade Hopper design, it is a handy and dependable device, a product of years of continuous improvement.

3. The highly reliable supply type

By our company manufacture the unique Shoot rail, supply the kinds of screws.

4. Reinforced Screw Locking Quality

The Pneumatic / Electric torque-controlled screwdriver of the famous brand in Japan is used. Furthermore, the applicable pneumatic/Electric torque screwdriver will be used according to the customer’s work piece locking torque requirements to achieve consistent fastening quality.

5. Customization and Stability

The stability of screw conveyance and the locking will be remarkably enhanced for the custom-made screws. The SEALS Automatic Screw Feed System is customized for your fasteners and specific application.

Specification

- Voltage: 220V, Single Phase

- Air Pressure: 5.5 kg / cm² / 85PSI

- L / W / H: 35 / 25 / 38 cm

- Net Weight / Gross Weight: 23 kg / 31 kg

- Capacity: 30 pcs/min.

- Torque: Refer to screwdriver capacity

- Volumn: M3 x 15 2000 pcs

- Driver Option : Sumake, Uryu, M&L (Air Screwdriver) or Sumake, Kilews Electric, Delvo (Electric Screwdriver)

Available Screw Chart

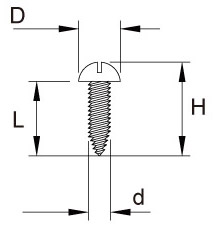

Listed below is the typical model of screw sizes that can be accepted for production. (Unit: mm)

Listed below is the typical model of screw sizes that can be accepted for production. (Unit: mm)

(Note) Special specification screws not included in this table also can be used. For details, please contact a serviceperson of this Company.

| Pan Head Round Head | Flat Head Oval Head | Binding Head | Truss Head | Max. L Dimension (L) | ||||

|---|---|---|---|---|---|---|---|---|

| Screw Head Dia. (D) | Min. H Dimension (H) | Screw Head Dia. (D) | Min. H Dimension (H) | Screw Head Dia. (D) | Min. H Dimension (H) | Screw Head Dia. (D) | Min. H Dimension (H) | |

| 4.6 | 8 | 4.9 | 8 | 5.2 | 9 | 12 | ||

| 4.5 | 8 | 5.0 | 8 | 5.3 | 8 | 5.7 | 10 | 16 |

| 5.5 | 9 | 6.0 | 9 | 6.3 | 9 | 6.9 | 11 | 20 |

| 6.0 | 9 | 7.0 | 10 | 7.3 | 10 | 8.1 | 12 | 22 |

| 7.0 | 10 | 8.0 | 11 | 8.3 | 11 | 9.4 | 13 | 22 |

| 8.0 | 11 | 9.0 | 12 | 9.3 | 12 | 10.6 | 14 | 22 |

| 9.0 | 12 | 10.0 | 13 | 10.3 | 13 | 11.8 | 15 | 22 |

| 10.5 | 13 | |||||||

Screwdriver Optional

The selection of suitable screwdrivers is a great concern for the quality of the work. In this respect, we select Sumake, URYU Pneumatic Screwdriver and Sumake, Nitto Kohki Delvo Electric Screwdriver as driver options for your choice. Please contact us for the detailed specification of screwdriver.

(Note) The torque values listed in the specification table are provided by Japan’s and Taiwan screwdriver manufacturer, which represents the values measured with the Torque Tester under the simplest conditions. During physical locking, the torque values measured will vary according to the utilization conditions.

Reviews

There are no reviews yet.